section-f4e0294

Why Poly? |

Plain and Simple... It Lasts! |

Concrete is the second-most used substance on Earth, only surpassed by water.

While it’s long-lasting, it doesn’t stay in good condition forever. Aged concrete is prone to all sorts of damage, making it both an eyesore and a safety issue.

Mudjacking and polyurethane injections are two of the most common concrete repair methods in use today. They have a similar purpose of repairing and leveling old or damaged concrete. Despite their similarities, it’s important to know what sets these two methods apart to choose the best method for your project.

|

Traditional mudjacking, or slabjacking, is a remedy that’s been used for decades to raise sunken slabs. Now there’s a newer, longer lasting alternative available from Liftech Concrete Leveling that replaces the sand and clay based grout mixture typically used for concrete leveling with a two-part polyurethane product that expands to fill voids, providing a cushion of support and to raise the concrete. The light weight polyurethane concrete lifting material is available in several formulas designed for different applications. One of the key benefits of using the polyurethane is that it is formulated with the exact characteristics needed for specific jobs. We can provide lifting foams that are engineered to support heavy loads such as raising highway and industrial slabs. Standard foams for raising sidewalks and other residential concrete. As well as foam designed to set up in, and displace water.

|

The two liquid components that combine and react to create the polyurethane foam are mixed at the tip of the injection gun. When this mixture is injected beneath the concrete it will flow like water into any voids present for about 15 seconds before the chemical reaction takes place. When this reaction takes place, the foam expands to 25 - 30 times it’s liquid volume within 45 seconds. Fifteen minutes after the material sets, it reaches full compressive strength. Because of the characteristics of the material and how it is delivered, polyurethane can cover a larger area in less time. Our polyurethane is 100% hydro-insensitive meaning it won’t break down in water, erode or leach into soils. The only thing in nature that will break down polyurethane is ultraviolet light. Because it is impervious to moisture the physical characteristics and volume of cured foam are unchanged by the frost or seasonal changes in our climate. Despite these benefits, you may be left wondering how long does foam jacking last? While mudjacking usually lasts 2-5 years, polyurethane can last much longer if properly maintained.

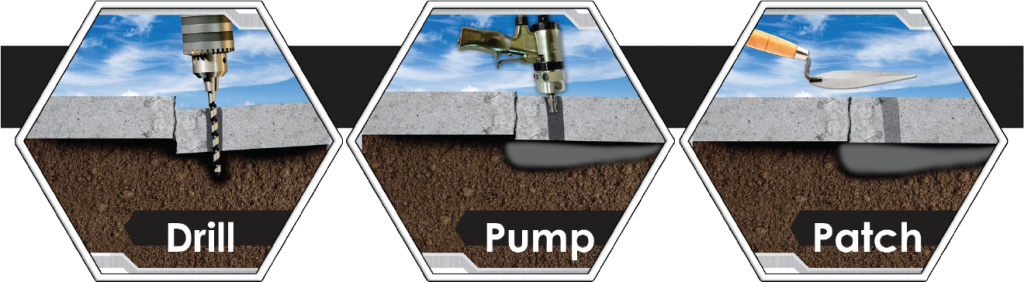

The application process of void filling and lifting a concrete slab with polyurethane is similar to traditional mudjacking. Polyurethane expands to lift the concrete versus building pressure to get lift with mudjacking. Another big benefit to the use of the polyurethane is that the size of the holes drilled in the concrete to pump the product are relatively small in comparison to the holes needed for mudjacking.

Whether your project is residential, commercial, industrial or municipal Liftech has many answers to Saskatchewan property owners concrete problems. Our polyurethane foams are the newest material being utilized in the concrete raising industry and Liftech is proud to be leading the way!

section-1153a6f

Visit our Case Studies Section to view some of our more unique projects. |